6 Layers FR4 HDI PCB Circuit a cikin 2oz jan karfe tare da Immersion Tin Surface An Kammala

Bayanan asali

| Model No. | PCB-A12 |

| Kunshin sufuri | Marufi Packing |

| Takaddun shaida | UL, ISO9001&ISO14001, RoHS |

| Aikace-aikace | Kayan lantarki masu amfani |

| Mafi ƙarancin sarari/Layi | 0.075mm/3mil |

| Ƙarfin samarwa | 50,000 sqm/wata |

| HS Code | Farashin 85340090 |

| Asalin | Anyi a China |

Bayanin Samfura

HDI PCB Gabatarwa

HDI PCB an bayyana shi azaman allon da'ira da aka buga tare da mafi girman yawan wayoyi a kowane yanki fiye da PCB na al'ada.Suna da mafi kyawun layi da sarari, ƙarami ta hanyar vis da fakitin kamawa, da mafi girman kushin haɗin haɗi fiye da aiki a fasahar PCB ta al'ada.HDI PCBs ana yin su ta hanyar microvias, binne vias da lamination na jeri tare da kayan rufewa da na'ura mai ba da hanya tsakanin hanyoyin sadarwa mafi girma.

Aikace-aikace

Ana amfani da HDI PCB don rage girma da nauyi, da kuma haɓaka aikin lantarki na na'urar.HDI PCB shine mafi kyawun madadin ƙidaya mai ƙididdigewa da tsada daidaitattun laminate ko allunan lanƙwasa.HDI ta haɗa makafi da binne ta hanyar da ke taimakawa wajen adana kayan gida na PCB ta hanyar kyale fasali da layukan da za a tsara su sama ko ƙasa ba tare da yin haɗin gwiwa ba.Yawancin kyawawan filayen BGA na yau da sawun sassauƙan guntu ba sa ba da izinin gudanar da lamuni tsakanin pads na BGA.Makafi da binne vias za su haɗu kawai yadudduka masu buƙatar haɗi a wannan yanki.

Fasaha & iyawa

| Abu | Ƙarfin samarwa |

| Ƙididdigar Layer | 1-20 yadudduka |

| Kayan abu | FR-4, CEM-1 / CEM-3, PI, High Tg, Rogers, PTEF, Alu / Cu Base, da dai sauransu |

| Kaurin allo | 0.10mm-8.00mm |

| Mafi Girma Girma | 600mmX1200mm |

| Haƙuri na Ƙimar allo | + 0.10mm |

| Haƙurin kauri (t≥0.8mm) | ± 8% |

| Haƙurin Kauri (t <0.8mm) | ± 10% |

| Insulation Layer Kauri | 0.075mm - 5.00mm |

| Mafi ƙarancin Layi | 0.075mm |

| Mafi ƙarancin sarari | 0.075mm |

| Out Layer Copper Kauri | 18 - 350 |

| Ciki Layer Copper Kauri | 17 - 175 pm |

| Ramin Hakowa (Mechanical) | 0.15mm - 6.35mm |

| Ƙarshen Ramin (Mechanical) | 0.10mm-6.30mm |

| Haƙuri na Diamita (Mechanical) | 0.05mm |

| Rijista (Makanikanci) | 0.075mm |

| Halayen Rabo | 16:1 |

| Nau'in Mashin Solder | LPI |

| SMT Mini.Nisa Mashin Solder | 0.075mm |

| Mini.Solder Masks | 0.05mm |

| Toshe Ramin Diamita | 0.25mm - 0.60mm |

| Hakuri na sarrafa impedance | ± 10% |

| Ƙarshe / magani | HASL, ENIG, Chem, Tin, Flash Gold, OSP, Yatsar Zinare |

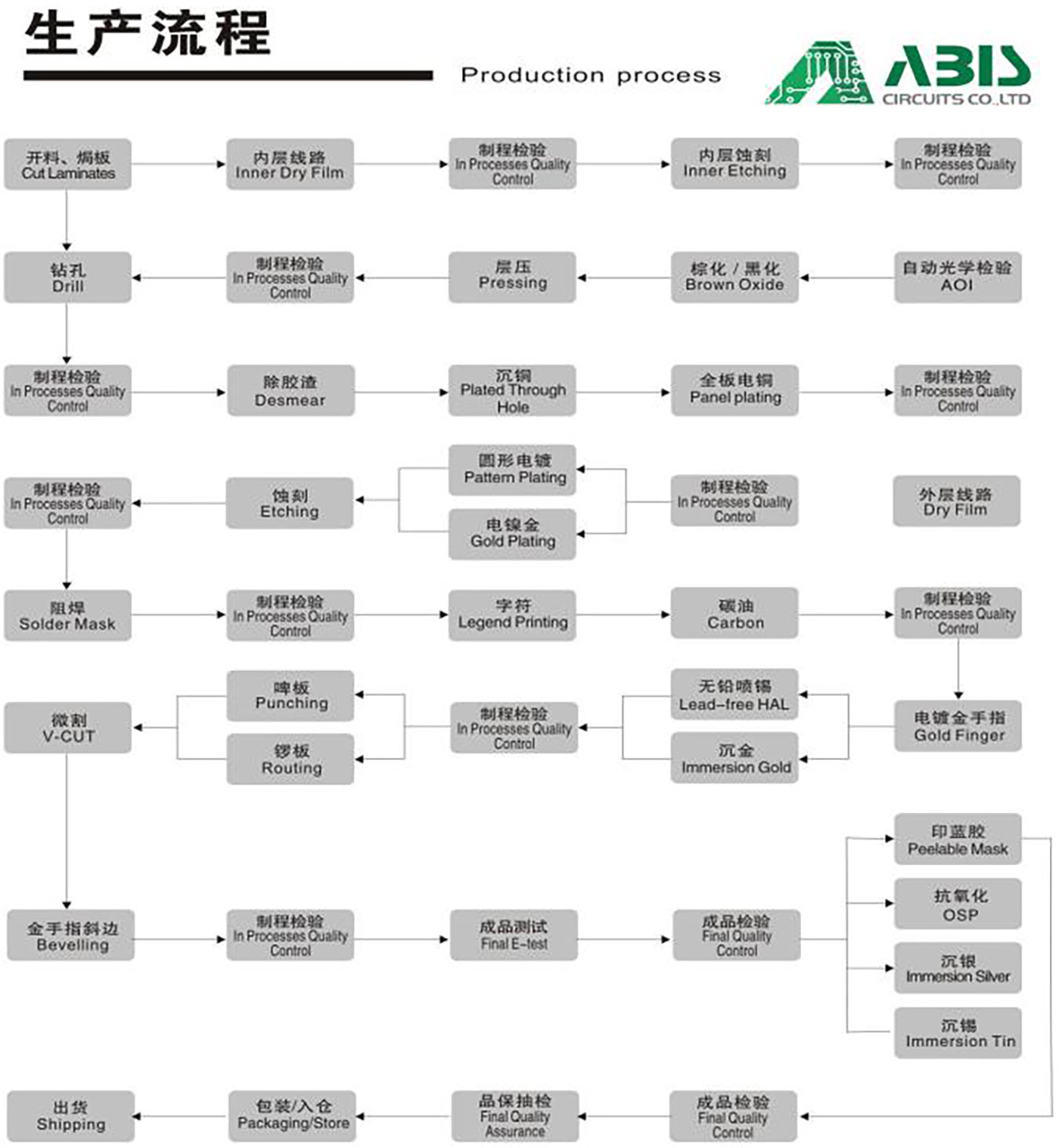

Tsarin Samar da PCB

Tsarin yana farawa tare da zayyana Layout na PCB ta amfani da kowace PCB ke tsara software / CAD Tool (Proteus, Eagle, Ko CAD).

Dukkanin matakan da suka rage na Tsarin Kera Na'urar Wutar Wuta Mai Tsari iri ɗaya ne da PCB Sided Sided ko PCB mai Sided biyu ko PCB Multi-Layer.

Lokacin Jagorar Q/T

| Kashi | Mafi Saurin Jagoranci | Lokacin Jagoranci na al'ada |

| Mai gefe biyu | 24h | 120h |

| 4 Layer | 48h ku | 172 h |

| 6 Layers | 72h ku | 192 h |

| 8 Layers | 96h ku | 212h |

| 10 Layers | 120h | 268h ku |

| 12 Layers | 120h | 280h |

| 14 Layers | 144h | 292h ku |

| 16-20 Layers | Ya dogara da takamaiman buƙatun | |

| Sama da Layers 20 | Ya dogara da takamaiman buƙatun | |

Motsi na ABIS don sarrafa FR4 PCBS

Shiri Ramin

Cire tarkace a hankali & daidaita ma'aunin injin rawar soja: kafin a saka ta tare da jan karfe, ABIS yana ba da kulawa sosai ga duk ramuka akan FR4 PCB da aka bi da shi don cire tarkace, rashin daidaituwa na saman, da smear epoxy, ramukan mai tsabta suna tabbatar da plating cikin nasara a manne ga bangon rami. .Hakanan, a farkon aiwatarwa, ana daidaita ma'aunin injin rawar soja daidai.

Shirye-shiryen Sama

Deburing a hankali: ƙwararrun ma'aikatan fasahar mu za su sani kafin lokaci cewa hanya ɗaya tilo don guje wa mummunan sakamako ita ce tsammanin buƙatar kulawa ta musamman da ɗaukar matakan da suka dace don tabbatar da cewa an yi aikin a hankali kuma daidai.

Ƙididdigar Ƙarfafawar thermal

An saba da ma'amala da kayan daban-daban, ABIS zai iya yin nazarin haɗuwa don tabbatar da cewa ya dace.sa'an nan kuma kiyaye amincin dogon lokaci na CTE (ƙididdigar haɓakawar thermal), tare da ƙananan CTE, ƙananan yuwuwar da aka sanya ta cikin ramuka za su gaza daga maimaita jujjuyawar jan ƙarfe wanda ke haifar da haɗin gwiwar Layer na ciki.

Sikeli

ABIS yana sarrafa kewayawa yana haɓaka ta hanyar sanann kashi cikin tsammanin wannan asarar ta yadda yadudduka za su dawo zuwa girman da aka ƙera su bayan an gama zagayowar lamination.Har ila yau, ta yin amfani da shawarwarin sikeli na masana'anta na laminate a haɗe tare da bayanan sarrafa tsarin ƙididdiga na cikin gida, don buga abubuwan sikelin da za su yi daidai da lokaci a cikin wannan yanayin masana'anta.

Machining

Lokacin da lokacin gina PCB ɗinka ya yi, ABIS ka tabbata cewa ka zaɓa yana da kayan aiki masu dacewa da ƙwarewa don samar da shi

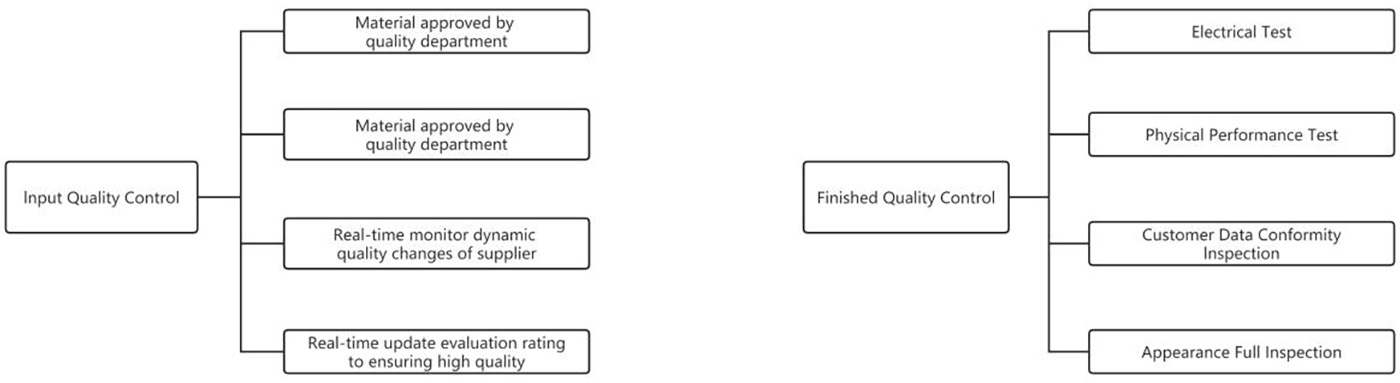

ABIS Quality Mission

Matsakaicin izinin abu mai shigowa sama da 99.9%, adadin ƙidayar jama'a a ƙasa 0.01%.

Abubuwan da aka ba da izini na ABIS suna sarrafa duk mahimman matakai don kawar da duk abubuwan da za su yuwu kafin samarwa.

ABIS yana amfani da software na ci gaba don yin ɗimbin bincike na DFM akan bayanai masu shigowa, kuma yana amfani da tsarin sarrafa inganci na ci gaba a cikin tsarin masana'antu.

ABIS yana yin 100% na gani da dubawa na AOI da kuma yin gwajin lantarki, gwajin ƙarfin lantarki mai ƙarfi, gwajin sarrafa impedance, ƙaramin yanki, gwajin girgiza zafi, gwajin solder, gwajin dogaro, gwajin juriya da gwajin tsabtace ionic.

Takaddun shaida

FAQ

Yawancin su daga Shengyi Technology Co., Ltd. (SYTECH), wanda ya kasance kamfani na biyu mafi girma na CCL a duniya dangane da girman tallace-tallace, daga 2013 zuwa 2017. Mun kafa dangantakar hadin gwiwa ta dogon lokaci tun 2006. The FR4 resin material (Model S1000-2, S1141, S1165, S1600) ana amfani da su musamman don kera kwamfutocin da'irar bugu guda ɗaya da mai gefe biyu da kuma allunan Layer Layer.Anan ya zo da cikakkun bayanai don bayanin ku.

Don FR-4: Sheng Yi, King Board, Nan Ya, Polycard, ITEQ, ISOLA

Don CEM-1 & CEM 3: Sheng Yi, King Board

Don Babban Mita: Sheng Yi

Don Cure UV: Tamura, Chang Xing (* Akwai Launi: Green) Solder don Gefe ɗaya

Don Hoton Liquid: Tao Yang, Resist (Wet Film)

Chuan Yu (* Launuka masu samuwa: Farar, Rawaya mai Imani mai siyarwa, Purple, Red, Blue, Green, Black)

), Fitowar sa'a 1

b), sa'o'i 2 na amsa korafi

c), 7 * 24 hours goyon bayan fasaha

d), 7*24 sabis na oda

e), 7*24 hours bayarwa

f), 7*24 samar da gudu

A'a, ba za mu iya karɓar fayilolin hoto ba, idan ba ku da fayil ɗin Gerber, za ku iya aiko mana da samfurin don kwafe shi.

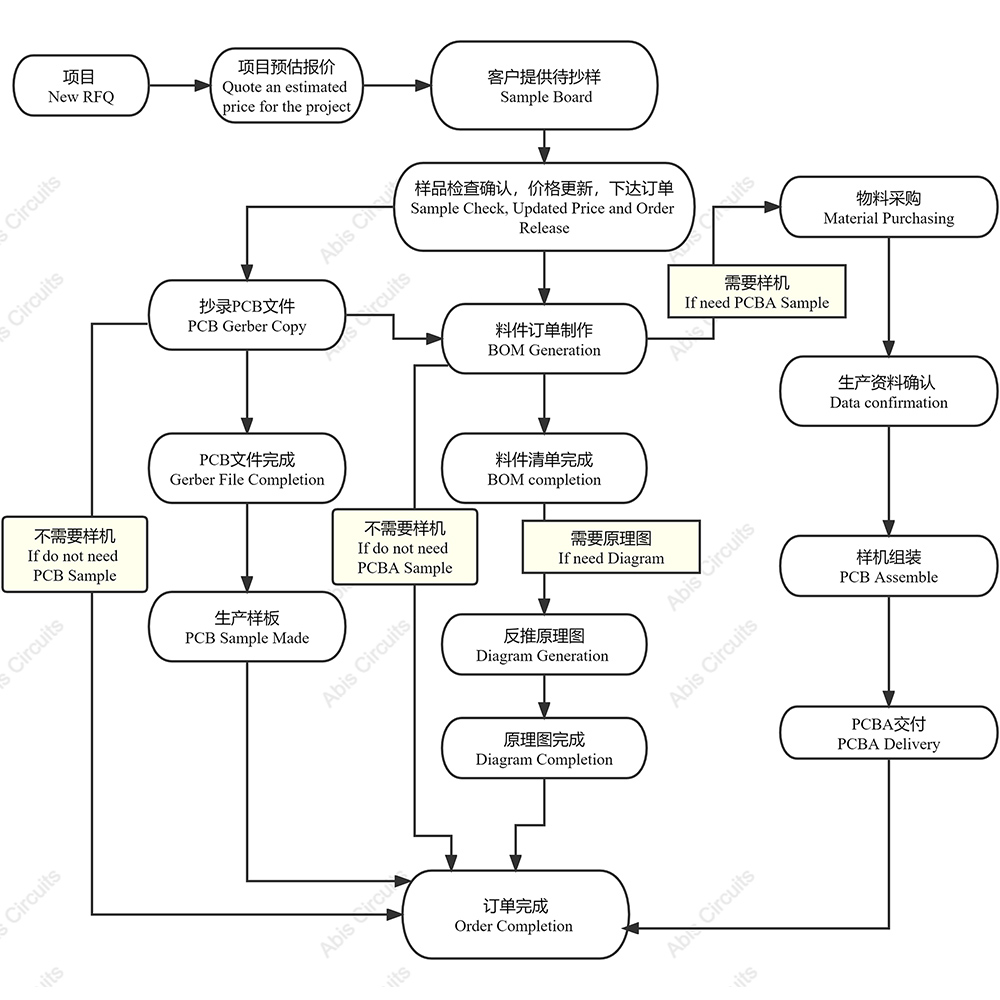

Tsarin Kwafi na PCB&PCBA:

Hanyoyin Tabbatar da Ingancin Mu kamar haka:

a), Duban gani

b), Bincike mai tashi, kayan aiki mai ƙarfi

c), Gudanar da impedance

d), Gano iyawar solder

e), Digital Metallo Gragic microscope

f), AOI (Binciken gani mai sarrafa kansa)

An duba cikin sa'o'i 12.Da zarar an duba tambayar Injiniya da fayil ɗin aiki, za mu fara samarwa.

Dubi kewaye da ku.Don haka kayayyaki da yawa sun zo daga China.Babu shakka, wannan yana da dalilai da yawa.Ba wai kawai game da farashi ba ne.

Ana yin zance da sauri.

Ana kammala odar samarwa da sauri.Kuna iya tsara oda da aka tsara na watanni gaba, za mu iya shirya su nan da nan da zarar an tabbatar da PO.

Sarkar kayan aiki ya faɗaɗa sosai.Abin da ya sa za mu iya siyan kowane bangare daga ƙwararrun abokin tarayya da sauri.

Ma'aikata masu sassaucin ra'ayi da masu kishi.A sakamakon haka, muna karɓar kowane oda.

24 sabis na kan layi don buƙatun gaggawa.Lokacin aiki na +10 hours a rana.

Ƙananan farashi.Babu boyayyen farashi.Ajiye akan ma'aikata, sama da kayan aiki.

ABIS ba shi da buƙatun MOQ don PCB ko PCBA.

ABlS yana yin 100% na gani da dubawar AOl da kuma yin gwajin lantarki, gwajin ƙarfin lantarki mai ƙarfi, gwajin sarrafa impedance, ƙaramin yanki, gwajin girgiza zafi, gwajin solder, gwajin aminci, gwajin juriya, gwajin tsabtace ionic da gwajin Aiki na PCBA.

ABIS ba shi da buƙatun MOQ don PCB ko PCBA.

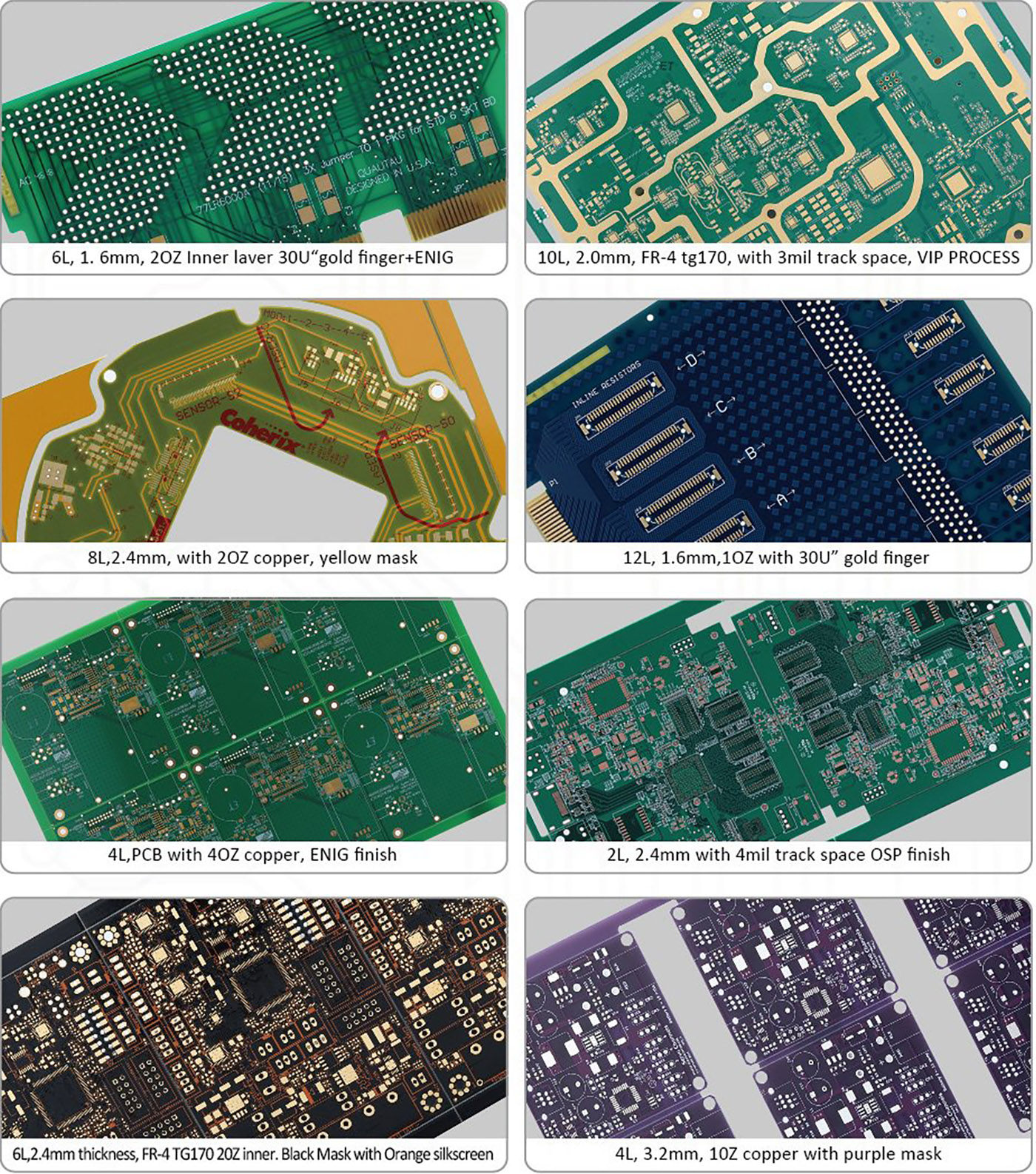

| Ƙarfin samarwa na samfuran siyarwa mai zafi | |

| Biyu Side/Multilayer PCB Workshop | Aluminum PCB Workshop |

| Ƙarfin Fasaha | Ƙarfin Fasaha |

| Raw kayan: CEM-1, CEM-3, FR-4 (High TG), Rogers, TELFON | Raw kayan: Aluminum tushe, Copper tushe |

| Layer: Layer 1 zuwa Layer 20 | Layer: 1 Layer da 2 Layer |

| Nisa Min. layi: 3mil/3mil(0.075mm/0.075mm) | Nisa Min. layi: 4mil/4mil(0.1mm/0.1mm) |

| Min. Girman rami: 0.1mm (ramin dirilling) | Min.Girman rami: 12mil (0.3mm) |

| Max.Girman allo: 1200mm* 600mm | Girman allo: 1200mm* 560mm(47in* 22in) |

| Ƙarshen katako: 0.2mm-6.0mm | Ƙarshen katako: 0.3 ~ 5mm |

| Kauri na jan karfe: 18um ~ 280um (0.5oz ~ 8oz) | Kauri na jan karfe: 35um ~ 210um (1oz ~ 6oz) |

| Haƙurin Ramin NPTH: +/- 0.075mm, Haƙuri na PTH: +/- 0.05mm | Haƙuri na matsayi na rami: +/- 0.05mm |

| Haƙuri na Shaci: +/- 0.13mm | Haƙuri na keɓancewa: +/ 0.15mm;Haƙuri na naushi: +/ 0.1mm |

| An gama saman: HASL mara gubar, zinari mai nutsewa (ENIG), azurfar nutsewa, OSP, platin gwal, yatsa na gwal, Carbon INK. | An gama saman: HASL kyauta, zinare mai nutsewa (ENIG), azurfa immersion, OSP da sauransu |

| Haƙuri na sarrafa impedance: +/- 10% | Haƙuri na kauri: +/- 0.1mm |

| Ƙarfin samarwa: 50,000 sqm / watan | MC PCB Samar da iyawar: 10,000 sqm/month |